It is well understood that the quality of washing machine spare parts decides the durability of the washing machine in the long run. As such, it becomes important that we understand how to identify the various washing machine components for the right quality and replace them with the right ones when needed.

This article will guide you toward accomplishing this goal. By the end of this article, you will learn and identify the various Laundry machine spare parts and will know where to buy these spare parts.

All this is done with a “washing machine spare parts name list” that explains the inner workings of a washing machine. The list includes the main components and spare parts used in a specific type of washing machine.

Let’s start now:

Washing Machine Spare Parts Name List

Since washing machines come in three different types; Front Loads, Top Loads and semi automatic washing machines(excluding Mini washers), we will have three different sections giving the washing machine parts list with an explanation.

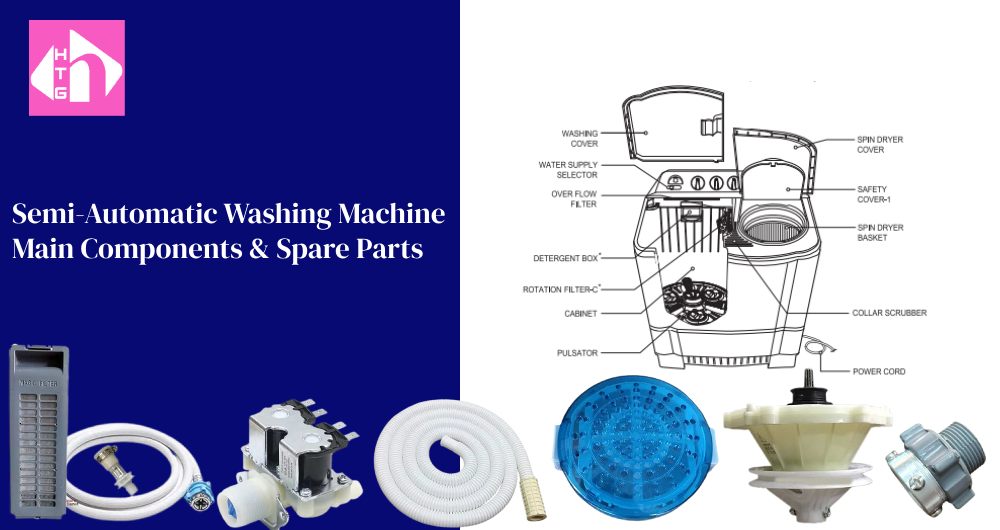

Our first list deals with semi-automatics.

Semi-Automatic Washing Machine spare parts name list.

1. Washing Machine Cabinet-The outer Body:

The outer body of a semi-automatic washing machine, in general, is made from high-quality thermoplastics like ABS(acrylonitrile butadiene styrene) or PCABS (a poly-carbonate ABS blend).

2. Wash Tub:

Made from plastics (some models have steel drums), the wash tub is the centre point where the washing activities (not spinning) are carried out.

3. Spin Tub:

Semi-automatic machines have a separate tub for spinning the laundry. These are plastic-made tubs, smaller in size than the wash tubs.

4. Control Panel:

The control panel in semi automatic washing machines comes with knobs. These knobs are used to provide instructions during the washing process to the washing machine. The instructions include activities like setting time, assigning a wash cycle etc.

The knobs present on the control panel of semi automatic washing machine are:

- Water Selector: Used to change the water flow direction between the wash and spin tub.

- Wash Selector: Used to assign a wash cycle; Gentle, Medium, or Strong wash.

- Wash Timer: Used to set a wash time for the wash cycle.

- Spin Timer: Used to set spin time.

- Drain Selector: Used to drain waste water from the wash tub or spin tub.

- Water Level Selector: Sets limit of water filling in the wash tub: High, Low or Medium.

5. Water Inlet Pipe:

The water inlet hose that connects the water tap to the washing machine for water supply.

6. Wash Agitator or Pulsator:

Semi-automatic washing machines may come with an agitator or pulsator that circulates the clothes in the wash tub during the wash cycle. Modern washing machines do not use agitators, instead, they come with advanced pulsators with embedded rollers in them.

7. Lids:

Lids are the outer covers of the wash tub and spin tub. They may come as made from plastics, fibre or glass.

8. Lint Filter:

Lint Filters capture lints and debris during the wash. It can be dismantled, cleaned, and reinstalled in the washing machine

9. Motor-

Motors drive the washtub and spin tub rotations during the wash process.

10. Belt

Belts connect the wash tub or Spin tub to the motor in the semi automatic washing machines.

11. Drain Pump

Available as plastic or metal-made, the drain pumps remove water from the drum.

12. Control Board or PCB

Control boards or PCBs are the electronic boards that facilitate passing instructions to the semi automatic washing machine through the control panel.

13. Water Inlet Valve

Available as plastic or metal-made, the water inlet valves regulate water flow into the wash tub or spin tub.

14. Water Drain Filter

It is a mesh-type structure that filters debris from the drain water.

Need to shop semi automatic spare parts?

Front Load Washing Machine Spare Parts Name List

1. Door

Front-loading machines have a horizontal, front-facing door that opens to load and unload clothes. They come mounted at the front, on hinges. It has a hook that is thermo-locked when the washing machine is in operation.

Door Glass

The door has a centrally mounted glass or a transparent polymer, allowing you to see the operations inside a washing machine. The glass design ensures safety against its weakening, due to the impact of some hard material striking the glass during the wash cycle, in the long run.

2. Door Seal or Gasket

A door seal (Silicon-based rubber) mounted on the circular cut-out of the door doesn’t allow water to splash out from the wash drum.

3. Door Lock

Front-loaders have a door lock mechanism that prevents the door from opening during operation

4. Drum or Tub:

The Washing machine drum assembly rotates the drum horizontally in front loaders. It doesn’t have an agitator, which allows for larger load capacities and gentler cleaning.

The Wash drum is the central part of the washing machine where the major operations like washing; rinsing; spinning, and drying occur.

There are two drums in a washing machine- The inner drum and the outer drum. The construction material for drums in front-load washing machines is stainless steel. The inner drums have holes through which the water accumulates in the outer drum and is brought under use during the wash process.

The outer drum may or may not contain a heating element. Again- it depends on the type of washing machine you are using. The drain pipe is also attached to the outer drum only. Some other components are found installed in the outer drum like the Pressure switch and water temperature sensor.

The front-load washing machines have paddles mounted on the wash drum to roll over the clothes while in motion.

5. Pressure switch

The pressure switch senses the water volume level in the washtub and cuts off the supply if not needed.

6. Temperature sensor

The temperature sensor detects the water temperature and cuts off the power supply to the heating element once it reaches the required temperature.

7. Suspension System:

Front loaders use a suspension system that includes springs, shock absorbers, or suspension rods to balance the drum’s movement.

8. Control Panel or the PCB:

The control panel for front-loading machines is usually located on the front of the machine, at eye level. It displays program related codes. The PCB (Printed circuit board) is a one-point station for the operation and control of the washing cycles.

These are all done by simply pressing some buttons. PCB lets you choose or set a wash program that suits your fabric quality or stain type. Wires from all corners- the different components like a valve, motor, sensor, heater, etc. are connected to the PCB through a jack.

Your Washing machine may not work if there is a short-circuit in the PCB or any washing machine’s electrical component. The PCB, if faulty, can be replaced with a new one. The PCB should be protected in high voltage fluctuations, the machine should be kept off.

9. Lint Filter:

Front-loaders often have a built-in lint filter, not visible from outside, that captures lint and debris during the wash.

10. Pumps ( Recirculation pump & Drain Pump)

A washing machine may come with two water pumps- The recirculation pump and the drain pump. The recirculation pump is used to re-circulate the water during the wash cycle.

The drain pump pulls the water out from the washtub and any extra water from the detergent dispenser drains during the process cycle. The operation of the pump is in line with the PCB directions.

11. Trap Filter

There is a Trap filter attached to the water pumps to trap some blockage like a coin or some cotton or clips and save pumps from getting damaged.

12. Drain Pipe

The drain pipe is another flexible hose attached to the outer wash drum through a valve and a drain pump. It operates in the direction of PCB. These pipes remove the wastewater from the drum when not needed.

13. Motor

Powers the drum’s rotation and functions.

Like we have a heart, a washing machine has a motor. All the agitation and turbulence inside the wash drum take place only because a motor rotates it in clockwise and anti-clockwise directions.

In previous years, front-load washing machines used to come with a motor that drives the inner drum through a belt and pulley or flywheel assembly.

New generation washing machines come with direct drive motors that come installed at the centre of the axis of rotation of agitators or pulsators.

The direct-drive motors provide better energy efficiency because of the fewer moving parts involved. The maintenance cost has also been reduced significantly with this new technology.

14. Water Inlet Valve

Available as plastic or metal-made, the water inlet valve regulates water flow into the drum. The water inlet valve operates on the directions received from PCB. They come installed on the washing machine’s rear side, and the water pipe is attached to them.

15. Water Inlet Pipe and Adapter

The inlet pipe is a flexible hose that comes with adapters at both ends. The adapters help better mount the water inlet pipe with a tap and at the washing machine’s rear end. The rear-end hose connection has also a filter that restricts any unwanted material in the inlet valves. These filters should be checked and cleaned at regular intervals. Washing machine installation close to tap allows proper fastening of adapter.

Some machines (Without a heating element) come with two flexible hose pipes, one for cold water and one for hot water inlet. Hence, there are two inlet valves, and only one operates at a time.

16. Heating Element

Heating Element is a metal piece that heats the water for warm and hot washes (if equipped).

17. Detergent Dispenser

Made from Plastics, the Detergent Dispenser holds and releases detergent, bleach, and softener. The dispensers may come with separate chambers for storing detergent and fabric conditioner. The user can easily take the detergent dispenser out of the washing machine for any maintenance need.

18. Suspension System/ Shock Absorbers

Composed of rubbers and springs, the Suspension system absorbs vibrations during the wash cycle.

19. Water Drain Filter

A mesh-type structure that filters debris from the drain water.

Need to shop Front Loader spare parts?

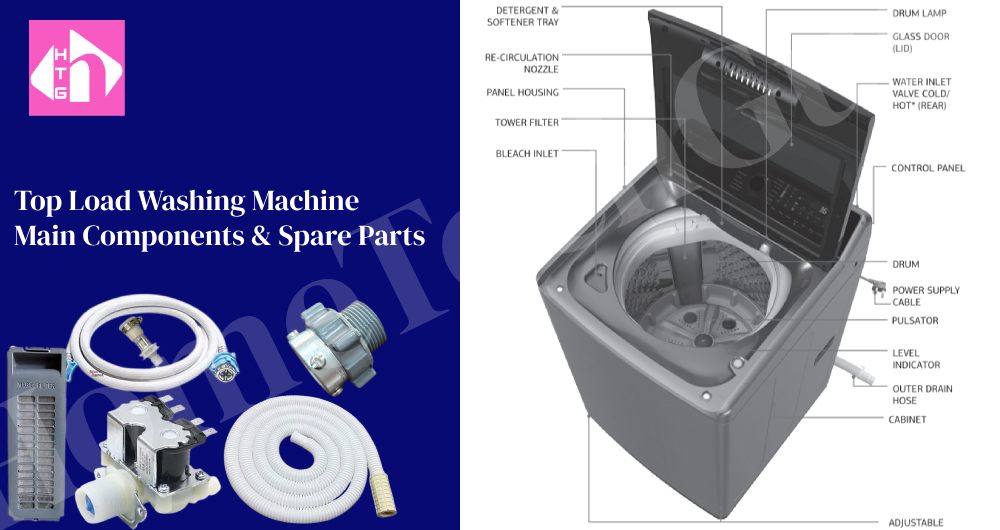

Top Load Washing Machine Spare Parts Name List

1. Agitator

Top-loading machines typically have an agitator, a central column with fins or paddles that move the clothes around for cleaning. Front-loading machines lack an agitator. The agitator is a perpendicular shaft-like assembly that helps to agitate the clothes during the wash cycle. Modern machines do not come with agitators. They have been replaced by pulsators and paddles for clothes fabric perseverance and better wash quality.

The impeller or pulsator

An impeller or pulsator is a rotating disc which creates turbulence in clothes during the wash cycle. Some modern machines also have rollers installed in the pulsator that move opposite to each other. The rollers/ propeller movement gives adequate friction to the clothes and helps to loosen the dirt better.

2. Lid/Door

Top-loading machines have a hinged lid on the top for loading and unloading clothes. The door has a centrally mounted glass or a transparent polymer, allowing you to see the operations inside a washing machine.

3. Drum or Tub

The drum in a top-loading machine is vertical, and the clothes are loaded from the top. The Wash drum is the central part of the washing machine where the major operations like washing; rinsing; spinning, and drying occur.

4. The Pressure switch

Senses the water volume level in the washtub and cuts off the supply if not needed.

5. The temperature sensor

Detects the water temperature and cuts off the power supply to the heating element once it reaches the required temperature.

6. Suspension System:

Top-loaders use a suspension system that includes springs, shock absorbers, or suspension rods to balance the drum’s movement.

7. Control Panel or the PCB

The PCB (Printed circuit board) is a one-point station for the operation and control of the washing cycles.

8. Lint Filter

Top Load washing machines may come with a lint filter installed in the wash drum, or with one that rests below the pulsator.

9. Pumps ( Recirculation pump & Drain Pump)

10. Trap filter

Attached to the water pumps to trap some blockage like a coin or some cotton or clips and save pumps from getting damaged.

11. Drain Pump

12. Motor

Powers the drum’s rotation and functions.

13. Water Inlet Valve

Regulates water flow into the drum.

14.. Inlet Valve and Adapter

15. Heating Element

Heats water for warm and hot washes (if equipped).

16. Detergent Dispenser

(Plastic) Holds and releases detergent, bleach, and softener.

17. Water Drain Filter

(Plastic, Mesh) Filters debris from the drain water.

Need to shop Top Loader spare parts?

How washing machine spare parts name list can help?

This article on “Washing machine spare parts name list” helps you to identify the spare part in your washing machine, learn about it and replace it with a genuine one.

Wrapping Up:

Washing machine maintenance, especially after 2 to 4 years of purchase, becomes a challenging task. A faulty washing machine may become a liability causing you unnecessary expenses and time wastage. As such, a thorough knowledge of various washing machine parts, and how they work may help greatly to quickly fix the washing machine.

We hope that the above-listed washing machine spare parts name list with the workings explained for these parts will help you in saving considerable time and money.

We hope you liked reading it. If so, please share it with your friends and loved ones.

Thank You.

FAQs

Where to buy Washing Machine Spare Parts?

Washing machine spare parts comes in various qualities and specifications. Maintaining these different parts in varying qualities becomes tough for local shop owners, unless a shop is a wholesaler, as their target audience is defined. They offer parts that are more frequently replaced in washing machines and that are commonly used in many washing models. Thus the best place to buy washing machine spare parts are large ecommerce platforms like Amazon or Flipkart.

maytag topload washer motor pulley diameter is 2.5imch but what is inner diameter where belt run . and what is motor shaft diameter thanks